Obuke

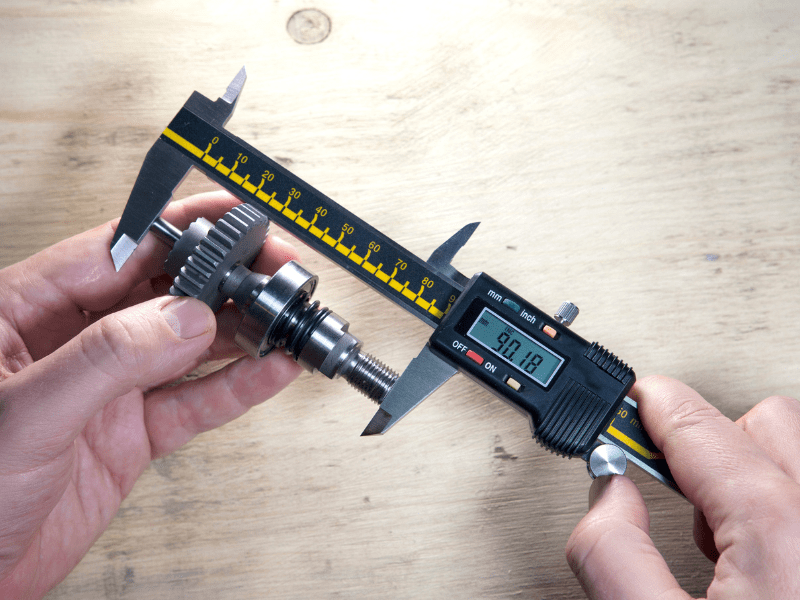

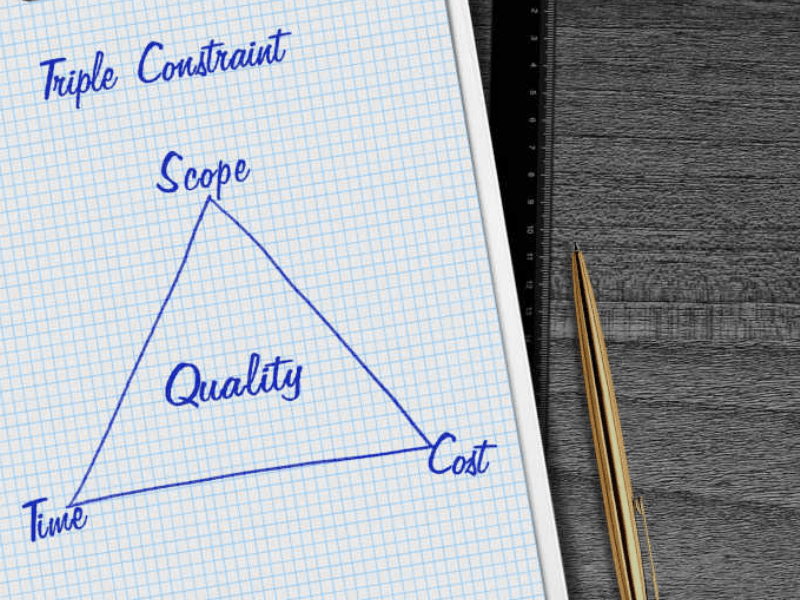

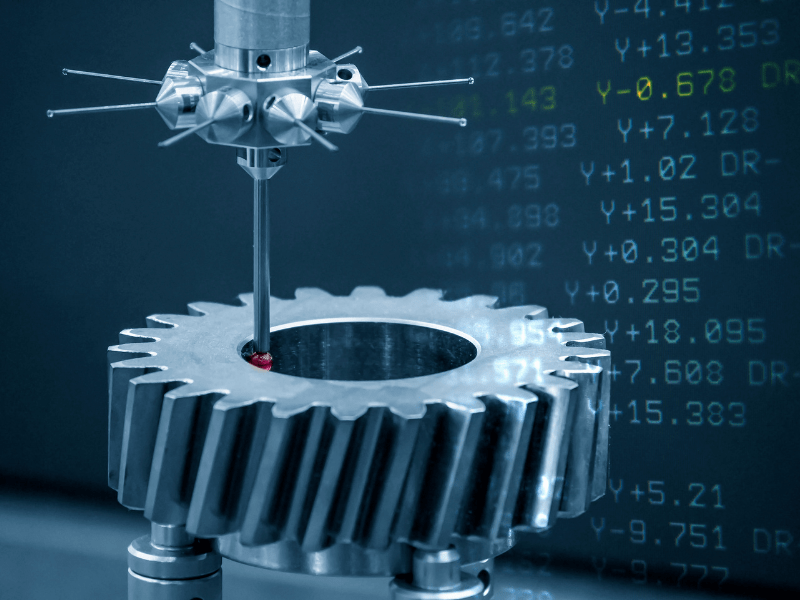

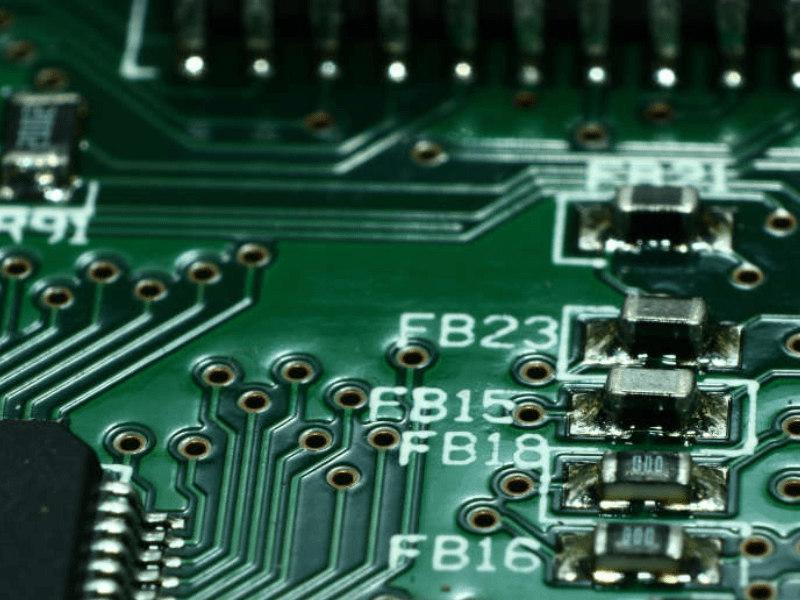

The training outlines the product approval process described in the PPAP manual issued by AIAG.

TARGET AUDIENCE OF THE TRAINING:

Employees of various departments within organizations who are responsible for approving their own and purchased products and processes, and approving suppliers.

TRAINING OBJECTIVES:

Participants will become familiar with the triggers for product approval according to PPAP, the relevant requirements, proper application for their own and purchased products, and documentation requirements.

TRAINING CONTENT:

PARTICIPATION REQUIREMENTS:

Knowledge of various methods such as FMEA, SPC,...

By mastering basic techniques, this training helps to alleviate and prevent stress.

TARGET AUDIENCE

Any person who is open to developing and maintaining inner harmony based on self-awareness.

TRAINING OBJECTIVES

After completing the course, participants will be able to identify and apply their own stress management techniques based on their personal development.

TRAINING CONTENTS

Knowledge about stress management

PARTICIPATION REQUIREMENTS

None.

The training introduces the basics of public speaking and presentation tool usage.

TARGET GROUP OF THE TRAINING

Any person who presents information or messages to a group verbally as part of their work.

TRAINING OBJECTIVE

After completing the training, participants are able to use their communication channels and available tools more consciously within presentation situations.

TRAINING CONTENT

PARTICIPATION REQUIREMENTS

None

Regionalni direktor prodaje i ključnih klijenata

E-mail:

VIHARI.adam@QFDGROUP.com

Office Leader - Novi Sad, Serbia

E-mail: beretic.marijana@qfdgroup.com